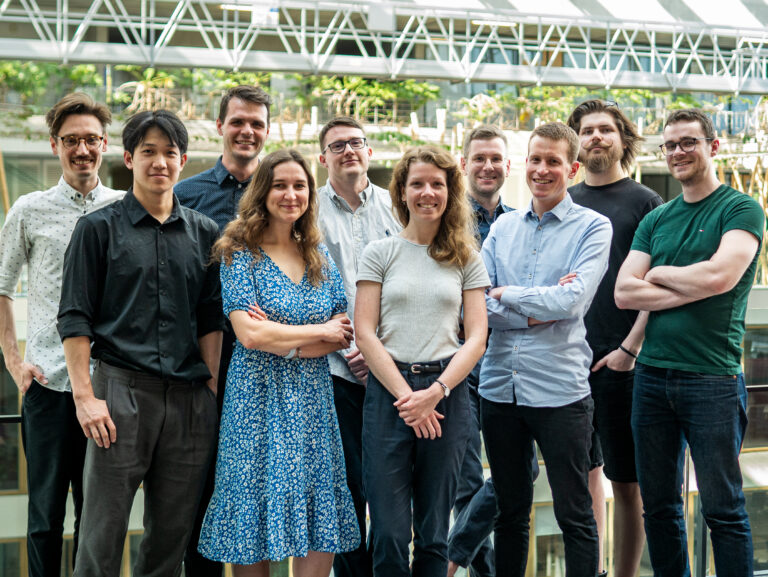

Hello Dita, thanks for joining us!

Thank you for having me.

You are in charge of Business Operations in RoboTwin, tell us more about your startup?

We provide no-code solutions for the manufacturing sector. RoboTwin tracks human motion and then generates a program for a robot, enabling it to replicate specific movements. With this capability, anybody can teach robots to perform tasks like painting, grinding, and many other manufacturing operations.

Who are your customers and how do you approach them?

Most of our customers are SMEs in the manufacturing industry. Recently, however, companies from other sectors have started approaching us because they are also facing robotics challenges and see potential applications in their own production processes. For us, it is essential to observe our customer’s operations firsthand so we can provide the best possible solution, which is why we currently execute a direct, on-site approach. Besides, we are partnering with system integrators, who offer our solution to the end-customers as part of new production lines.

Who came up with the idea of RoboTwin?

RoboTwin was founded by three co-founders three years ago. The original concept came from Megi Mejdrechova’s research – she was the one who first developed this idea.

You’ve spent a few years in Česká Spořitelna, Accenture, SAP or EY. And now you are in a startup. Does your previous career and gained experience help you in building RoboTwin?

Definitely. Startups are the kind of environment where experience from consulting or various corporate departments truly comes in handy. One major advantage is the technical foundation from my previous roles in the automotive, IT software, and technology consulting sectors. Even though my work has always been mostly business-oriented, collaborating with engineers earlier in my career made it easier to transition into robotics. Plus, having focused on the B2B sector since my first job during my bachelor’s degree has been beneficial, as it has its own unique demands.

Congratulations on being a part of Technological Incubation! Was it difficult to get in?

Thank you! Yes, 196 startups applied, and we were selected alongside 54 others. The application process was definitely challenging, with multiple selection rounds. But we are happy to be part of it.

What was the hardest part about it?

Time was the major factor. Preparing all the materials was time-consuming. Writing the incubation plan was tricky as well because what you write is something you’re committed to fulfilling, so it has to be carefully thought out.

If there are any readers considering applying to the next run of Technological Incubation, what would your advice to them be?

Take your time to develop a clear, focused plan. The process is competitive, so highlight what sets you apart and how your product can make a real impact. And also, be ready to commit, as the incubation program requires dedication to bring your plan to life.

And what is the most useful part of being incubated by it?

You get into the network of other cool startups in the Czech Republic, supported by many experienced mentors with years of experience. It is not only about the financing, it is about receiving guidance to develop the product further. And, also meeting many different startups during the events that CzechInvest prepares, gives you a lot of new inspiration and motivation.

There is a deadline for application for the 5th run of Technology Incubation, would you recommend to the Czech startups to send an application? If yes, what would be the “selling pitch”?

Absolutely. Programs like this are a great opportunity for Czech startups. Even if you are not selected, you can still reapply for another funding. The experience itself is valuable. So if you have a unique idea that can improve efficiency or bring innovation, go for it. The support network, mentorship, and funding are great resources to help you grow your business.

What are your goals for the remainder of the Technology Incubation or even beyond?

During the program, we have been developing a new robot-teaching technology specifically for grinding applications. In the future, we aim to be able to automate any repetitive manufacturing movement. And in the long term, we want to improve production lines on a broader scale. We currently have our first customers in Czechia and the USA. And we want to expand into larger markets.

What excites you most about the future of RoboTwin and robotics in general?

The potential for robots to assist in complex, dirty and unhealthy tasks is incredible. With RoboTwin, we envision a future where robots can learn human movements intuitively and help manufacturers save time, improve quality, and keep people safer. We are excited to be part of that transformation in the industry.

Thank you for joining us and wish you the best of luck!

Thank you too.